Welcome to Our Website

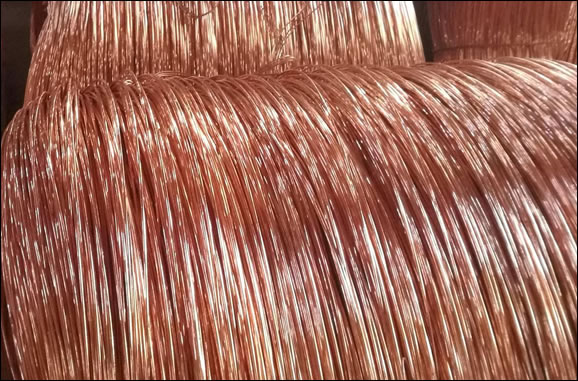

Copper coated wire is a versatile and widely used type of wire that finds its applications in various industries such as electrical, electronics, telecommunications, and construction.

High Carbon Steel Wire, Brass Coated

Size - 0.12 mm ( + - 0.002 mm )

Ovality - 1.5 ~ 0 um

Breakage Load - 37 +/- Newton

Spool Length - 760 KM / Spool

Application - For Cutting Solar Panels Into The Required Size

Classification of Copper Coated Wire:

Copper coated wire can be classified based on various factors such as the core material, application, and coating thickness.

Core Material:

Steel Core: Copper coated wire with a steel core is commonly used in applications requiring high tensile strength and durability. The steel core provides mechanical strength while the copper coating enhances conductivity and corrosion resistance.

Aluminum Core: In some cases, copper coated wire is manufactured with an aluminum core. This type of wire is often utilized in applications where weight reduction is a priority.

Application:

Electrical and Electronics: Copper coated wire is extensively used in the electrical and electronics industry for applications such as wiring harnesses, transformers, motors, generators, and electrical connectors. Its high conductivity ensures efficient transmission of electrical signals.

Telecommunications: Copper coated wire is also employed in telecommunications for applications like telecommunication cables, coaxial cables, and grounding wires.

Construction: In the construction industry, copper coated wire is utilized for reinforced concrete structures, pre-stressed concrete, and other structural elements requiring high tensile strength.

Specifications of Copper Coated Wire:

Tensile Strength: Copper coated wire exhibits excellent tensile strength, which is typically in the range of 600 MPa to 1200 MPa for steel core wire.

Elongation: The elongation or stretchability of copper coated wire is an important characteristic. It allows the wire to withstand mechanical stress without fracturing. Typically, the elongation of copper coated wire ranges from 10% to 30%.

Roll Size and Weight Range: Copper coated wire is usually available in rolls or spools for easy handling and transportation. The roll size can vary, but common weights range from 10 kg to 1000 kg.

Wire Diameters: Copper coated wire is available in a wide range of diameters to suit different applications. Common diameters range from 0.8 mm to 5.0 mm.

Properties of Copper Coated Wire:

Conductivity: Copper coated wire offers excellent electrical conductivity due to the high conductivity of copper. It ensures efficient flow of electrical current, minimizing energy loss.

Corrosion Resistance: The copper coating provides a protective layer that enhances the wire's resistance to corrosion, making it suitable for outdoor and harsh environments.

Anti-Magnetic Properties: Copper coated wire exhibits anti-magnetic properties, which is advantageous in applications where magnetic interference needs to be minimized.

Packing of Copper Coated Wire:

Copper coated wire is carefully packed to ensure its protection during transportation and storage. It is commonly packed in wooden or steel reels/spools to prevent damage and tangling of the wire. Additionally, the wire is often wrapped with plastic or paper to provide further insulation and protection against moisture.

Uses of Copper Coated Wire:

Electrical Applications: Copper coated wire is widely used in electrical applications such as power transmission and distribution, electrical equipment manufacturing, and residential wiring. Its high conductivity and corrosion resistance make it an ideal choice for these applications.

Automotive Industry: In the automotive sector, copper coated wire is employed in wiring harnesses, connectors, and other electrical components. It withstands the demanding conditions of the automotive environment, ensuring reliable performance.

Telecommunications: Copper coated wire finds extensive use in the telecommunications industry for applications such as telephone cables, data transmission cables, and networking cables.

Construction Industry: The construction industry utilizes copper coated wire in reinforced concrete structures, pre-stressed concrete elements, and structural components requiring high tensile strength.

Art and Craft: Copper coated wire is also popular in the art and craft community due to its malleability and versatility. It is used in jewelry making, sculptures, and various other creative projects.

4mm copper coated wire in the coil with the following specifications:-

a. Tolerance of +0/- 0.05mm, on the wire diameter

b. Tensile strength of 450-650Mpa

c. Weight of the coils,600-800kg per coil

d. Maximum OD of the coils-800mm

e. ID of the coils -480mm

Round copper wire

Diameter: 1,07mm +0,01 / -0,02mm

Tensile strength: 300 – 400 N/mm2

Copper coating: 25 g/m2

Raw material: C4D (or U53042)

%C < 0,06 / %Si < 0,30 / %Mn: 0,30 – 0,60 / %P < 0,035 / %S < 0,035 / %Al < 0,01 / %Cr < 0,2 / %Cu < 0,3 / %Mo < 0,05 / %Ni < 0,25

Material to be annealed after copper coating.

ID: 400mm

OD: 800mm

Height: 1000mm